A little more than a month before the opening of "Red in Progress. Salone del Mobile.Milano meets Riyadh", the Salone del Mobile.Milano’s event in Saudi Arabia, the celebrated architect and designer explained to us what the Business Lounge he has designed for the occasion will look like, and what stories its interior will tell about Italian design

Solaris Community, the platform that helps companies regenerate waste

Solaris

A worldwide network of more than 250 experts helps businesses and institutions embrace the circular economy. To ensure that valorizing waste becomes beneficial, and lies within everyone’s reach.

It is often said that every piece of waste not reused is an opportunity missed. Too bad that for many companies it is difficult to reuse their waste beneficially, not from a lack of purpose but the absence of the requisite skills. The regeneration of industrial waste often calls for specific expertise, requiring to be tailored to the features of each production. Hence the ability to do it and who to turn to is not obvious.

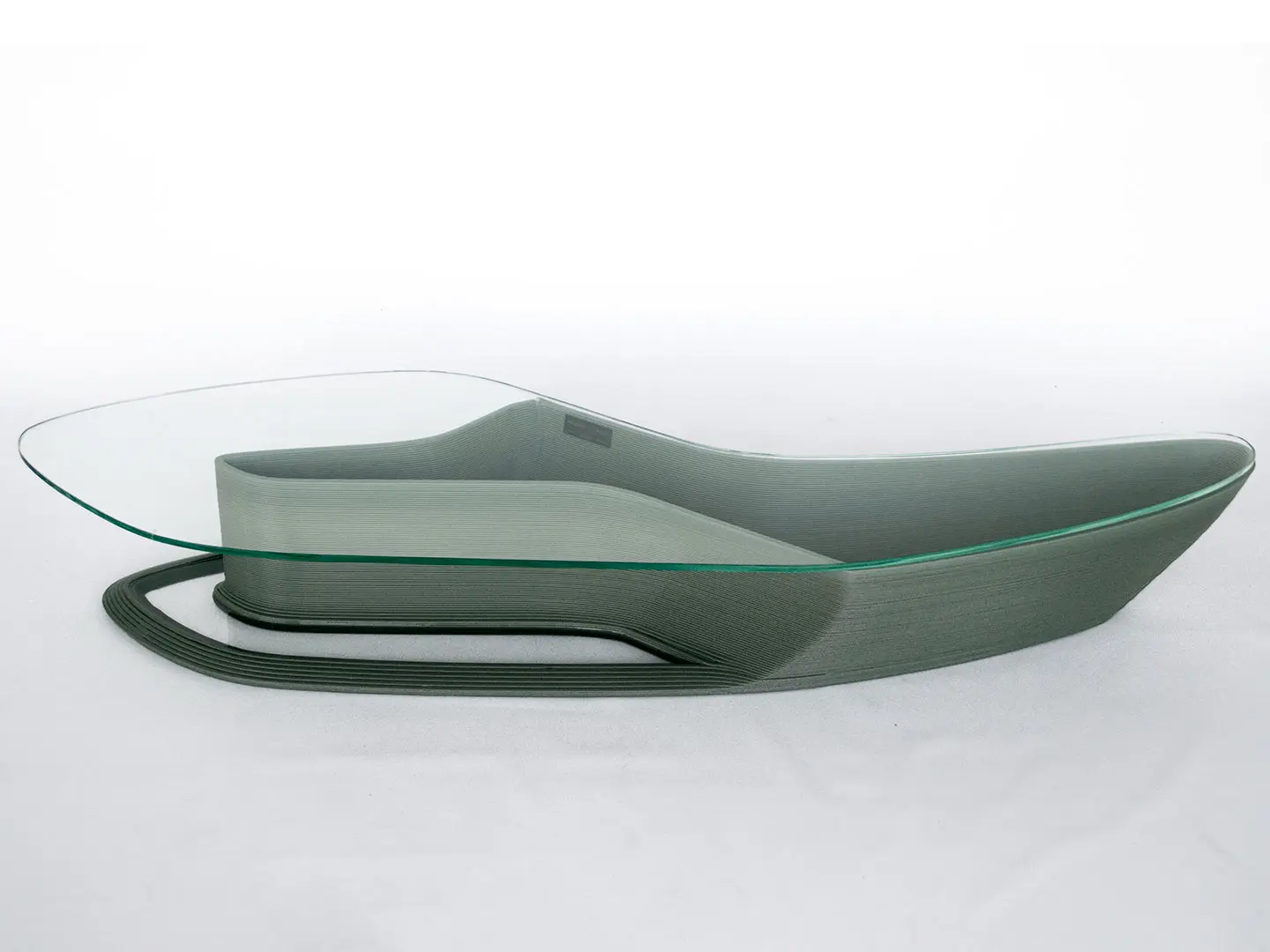

Solaris Community was founded as an answer to this problem. Thanks to a network of over 250 partners worldwide, the platform helps companies work towards a circular economy, identifying the finest experts able to support product development, whether they are designers – such as Iris van Herpen or Karim Rashid – researchers or engineers in the fields of chemistry or mechanics. Solaris also acts as a consultant on the best innovative materials, and as a bridge between different businesses, so that the waste of one is transformed into the resources of the other.

Active only since 2019, Solaris Forma can already boast significant successes, such as experimenting with the reuse of plastic waste in high fashion and furniture, or recycling beverage cartons, as we will discover at the next Milan design week. With the founder of Solaris, Zehao Liu, we discussed how to close the circle, an expression that hopes for the “end of life never” of the materials we work with. So that, thanks to research and design, sustainability and innovation become a practice within everyone’s reach.

Solaris Community’s most impactful contribution to closing the loop comes through our “cross-industry closed loop” projects. These collaborative initiatives bring together our diverse network of 250+ members, spanning industries like fashion, furniture, architecture, and electronics. In these projects, Solaris acts as a dynamic hub, orchestrating the entire closed-loop supply chain—taking waste from one industry and transforming it into co-branded products for another. Additionally, we bring together specialists with cross-industry experience to navigate challenges related to closed-loop circular systems and facilitate collaboration. As the central organizer, Solaris ensures these circular projects are not only possible but premium quality and innovative.

Achieving closed-loop circularity is challenging, with obstacles varying depending on company size and industry. The primary challenge lies in the existing linear supply chain model, which is designed for efficiency and profitability, not circularity. Businesses are focused on making profits to survive and grow, and circular models often require significant investment and structural changes. For small- to medium-sized businesses, one major barrier is production volume. While designers are increasingly incorporating sustainability and recyclability into product designs, smaller brands often struggle to convince suppliers to adopt circular manufacturing processes. Larger companies face a different set of challenges. While they generally have the resources to invest in circular initiatives, the complexity of their internal structures often slows progress. Moreover, the ROI from circularity may not always be immediately clear, which adds another layer of difficulty.

Since our members come from diverse sectors, each with its own set of standards, some variation in compliance is inevitable. This fits well with our “cross-industry closed loop” model, where recycled materials from one industry (such as fashion or electronics) are used to create products in another (like furniture or architecture). As a result, manufacturing processes often need to be modified to meet the specific standards of the receiving industry. Navigating this requires a deep understanding of both industries, which is where the strength of the Solaris Community comes in. We bridge these knowledge gaps and ensure that the product development process remains smooth and efficient. By collaborating across sectors, we tailor solutions that meet both regulatory and manufacturing requirements, ensuring successful outcomes despite varying certifications.

One standout success is our collaboration with Evian, which demonstrates the power of our “cross-industry closed loop” model. When we learned that Evian’s marketing team had a long-term strategy to develop co-branded products with fashion brands, we saw an opportunity. Solaris stepped in to create an EU-based supply chain that would upcycle this remaining waste into a premium fabric collection, Liquid Fabric. The fabric’s unique, fluid liquid reflection symbolizes its origin, beautifully transforming waste into a valuable new material. Liquid Fabric was first showcased in a haute couture dress by Iris van Herpen and later in a capsule collection by Balmain X Evian, demonstrating both the aesthetic and commercial potential of this upcycled material.

Solaris’ mission is an extension of the UN’s vision for sustainable development: creating a circular economy, reducing waste, and fostering collaboration to build a more sustainable future for all. The UN’s Sustainable Development Goals (SDGs), especially those focused on responsible consumption and production (SDG 12) and climate action (SDG 13), directly align with Solaris’ mission and underscore the need for systemic, innovative solutions to global environmental challenges, a vision we embrace in everything we do. Additionally, the UN program’s emphasis on capacity building and knowledge sharing has shaped Solaris’ approach to developing expertise across sectors. Achieving true sustainability requires more than just new technologies—it requires the right knowledge, infrastructure, and partnerships. Solaris has created a network of specialists who bring unique expertise to every project, helping businesses navigate the complexities of circularity and supporting systemic change.

I understand why some might feel that way, as historically, repurposed materials were sometimes viewed as lower quality. However, this perception is quickly changing due to advancements in design and technology. Repurposing materials doesn’t mean sacrificing quality—it means reimagining how we approach materials, design, and production with a focus on both sustainability and performance. With the right expertise and a commitment to innovation, we’re proving that repurposed materials can be both beautiful and cutting-edge.